Jimmy's A/C Power System

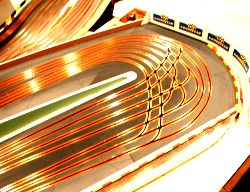

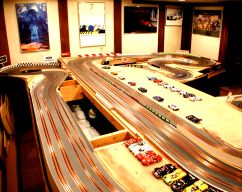

Jimmy's Northline Raceway A/C Operating System I'd like to share information with other model car racers on a system that we have been using to power Northline Raceway for the past 20 months. We have been testing this system of running two independently controlled cars in one slot, powered by an AC train transformer, with surprisingly successful results. We have now, confidently put this system to full time use. The inexpensive benefits could affect how you design your next routed track. Or, even prompt you to add passing lanes onto your existing layout. Two cars independently driven in each slot with improved control Northline Raceway is a wood routed track nearly 140 feet long that was originally designed to run 4 cars. (See Model Car Racing #14) Drivers have the ability to change over to slots routed for them on either side of the road. This creates two separate ways to do a lap, which allows cars to pass or block on the scale width roadway. By clustering the slots into two groups, with just enough room between the groups to allow cars to pass, the over all width of the track is reduced. A narrower roadway helps any track design by allowing a longer layout in the same space. It is important to understand that adding passing lanes that cars get switched over to, will actually reduce the track's width. (We'll do the math further on to prove it to you) This dramatically increases the linier feet of racing, since more race track can be designed into the same area. Note that without a lane changing mechanism and a separate passing slot cut somewhere around the track, two cars can run in the same slot, but will not be able to pass one another. This restricts the lane sharing benefits of this AC system to custom designed routed tracks that have a lane changing mechanism and passing lanes built in. But, the benefits of nearly twice the racing, in the same space, for very little money is worth breaking from the conventional slot car "pass everywhere with eyes closed" mindset on your routed track. Rediscovering old technology. Fifteen years ago, when I knew that the lane change feature built into the hairpin on Northline Raceway worked well, I realized that if I could get two cars running in the same slot they would be able to get by each other by using the passing lanes. This would almost double the number of cars racing on my track. I began looking into digital train control without much luck. Then my brother, an Electrical Engineer, and I spent a year trying to set up a pulse-width modulating system. But that system, like digital, was complicated to add to a routed track and not user friendly in terms of visitors bringing over their conventional cars. Nothing worked well on our wood track and we were about to give up. However, I remembered clearly that many years ago there was a TV commercial showing Eldon cars changing lanes. Also, I recalled that in the mid sixties my brother and I got Eldon cars that were labeled "Selectronic". I was upset when they would not run on my standard Eldon track. I cut out this electronic thing (diode) in line with the motor, and bingo… the car worked. Also, my conventional DC Eldon transformer went dead that year and the jerk at the local hobby shop dumped a "Selectronic" transformer on me. The cars just sat on the track buzzing. Since it was an electronic item he would not take it back. At 13, that was an event that was hard to forget since $12 was a fortune to me then! Those memories led us to an idea that has improved the performance of Northline Raceway 200%. My brother theorized that the buzzing must have been because the Selectronic transformer was sending an Alternating Current to the track. Alternating the polarity 60 times each second. I insisted that if Eldon could get two cars to share a lane this way, so could we. The results of almost two years of testing have left us confident that this simple system has more than one benefit over the typical DC power that model racers use today. Initially we planned to run this AC system only when we wanted 8 cars on the track. We get such realistic control of the cars that we now race even just two cars on AC. How AC powers two cars in a slot with independent control By powering the track with a variable A/C current (old, used, cheap Lionel train transformer) and rectifying the supply with a $.10 diode wired into each car, we are able to send two separate signals to one lane. Also, a second diode must be put into the circuit of the controller that is coordinated with the diode in the car it controls. The diodes must be in the same direction in the circuit. The diodes at the controllers can be placed in line with either the black or white leads of the controllers but must be in sync with the diode of the car it controls. The red brake line must be disconnected at all times running the AC two car system. Diagram to add diode into car wiring : pdf Diodes block the flow of power in one direction and allow current to flow in the opposite direction. Our work shows that any diode will work. We use diodes bought from DIGI-KEY.COM. Mail ordered in bulk of 100 for around $20. One controller and car in the lane is referred to as car "A" and the second controller and car in that same slot is "B". 60 times each second, power from the AC transformer reverses polarity. The diodes in the circuit of car A block the flow of power to it whenever it is not the current who's polarity allows it to move forward. The same with car B, which has it's polarity to it's motor reversed. When car A is coasting 60 times each second, car B gets power through the B controller. When car B coasts 60 times each second, car A gets power through the A controller. Yes, each car coast for half the time, but with almost twice the voltage pulsing 60 cycles a second, it's tell tale growl is all you see or hear. The cars equipped with lighting circuits still work just fine. Instead of 4, we can now run 7 race cars at one time on our track, with the 8th car being a pace car that leads the field. The pace car shares lane 4, which on our track, runs down the center of the roadway with no lane change capabilities. When the field is grouped for the rolling start, the safety car picks up the pace, then pulls into the pits to clear the way for the 7 cars roaring to the starting line. The system works very well, and is quite inexpensive. Once you know the combination and placement of diodes it is cheap and easy to do. Conventional track design vs. the passing lane design with switching capabilities In order to understand the narrow track width design advantages allowed by a system that can independently run two cars in one slot, we need to compare the road width of a conventional routed track (slots around the layout spaced widely apart) vs. a track designed with an extra passing slot cut around the course for each car (allowing cars A & B sharing a slot to pass or block each other when switched to a passing slot cut on the opposite sides of the road). If we were to design a conventional DC track to run (6) 1/32 scale cars using 1/8" routed slots, it would require a min of 2.75" between slots, and 1.75" on either side for minimum track edge clearance. The total road width on this layout would be 18". (Of course, track width at turns would be expanded, but for this comparison we'll compare just the straight sections) Now, let's design a track to race (6) 1/32 scale cars on the AC system that will run two cars independently in one slot. Since two cars can share the same slot, we need to cut 3 slots in a tight group spaced 3/4" apart, and 1.75" from the tracks edge. Then we cut a second group of 3 slots, again 3/4" apart, 2.75" from the first group. Whenever a driver chooses to switch to the second group of 3 slots (the "passing lanes") the 2.75" space between the groups allows any car to pass any other car when they run in slots on opposite sides of the track. The total width of this roadway, allowing 1/8" per slot and another 1.75"min distance to the other edge of the track is now 9.25" The benefits of a narrower roadway The conventional design required 6 slots cut to allow 6 cars to race on an 18" wide track all passing at will in an unrealistically typical "slot car" manner. With the "passing lane" design and the AC system, 6 slots would also need to be cut. However, since the AC system allows two cars to inexpensively share a slot, we now can have 6 cars racing on a track 9.25" wide. That's almost half as wide! This allows for double the racing layout in the same space ! The track design running 6 cars on this narrow roadway can be designed to be nearly twice as long. Plus blocking and passing makes for much more realistic and exciting model car racing. If you are designing a miniature road course, by adding this passing slot in addition to the regular slot, and building in a lane change mechanism, you can now run double the cars, nearly double the distance in the same space for the cost of an old train transformer and some $0.10 diodes. A few wood track builders, who have investigated these ideas, are currently in the process of revising their plans to go from 2 cars D/C to 4 cars A/C by adding these extra slots to their track design. One efficient track builder in Grand Rapids MI. is even planning to use a simple auto choke cable and spring to actuate his manual lane change switches. This pull cable, for changing into the passing lane, is far simpler than using an electronic solenoid to drive the switching mechanism that we now use on Northline raceway The added benefits of a pulsing higher voltage The car control is fantastic! You can make a car creep into the pits or go balls out down the straight. The cars growl as they go around, which everyone agrees sounds cool. Although the motors run warmer, (not hot) the GWLTRSCIOGBs (Guys Who Like To Run Slot Cars In Other Guys Basements) here in Michigan have thrashed over 75 different cars for many hours with no negative affects. There are tracks in this area, without lane changing capabilities that are now running strictly AC, just to take advantage of this added control. In this case, diodes in the cars are not required. One diode per controller is wired in either the black or white controller leads and the track is powered by a variable AC train transformer. Again, the red controller leads must be disconnected. Not only is control improved, but there is an added benefit for copper taped tracks. The oxidation on the copper is no longer such a hindrance since the cars run on twice the voltage for half the time. The 16 to 18 volts burns through the dust and oxidized copper film. No more repeated warm up laps to polish in the copper so cars don't stall. A big plus with this system is that when guys come over with regular cars, no diodes installed, they can still put their car right onto the track and run perfectly one car per lane. With the same great sound and control. Unlike unique digital cars, it's not a problem as long as the lane is not shared by another. But, any standard car can be made to run two in one slot with the simple addition of the inexpensive diode wired in line with the motor. We have not had the D/C power supply on much since Northline Raceway got the new A/C system going. Actually, the only time the DC power supply goes on now is when we do a comparison demonstration to highlight the difference in control to new drivers. They all agree, that although the lap times drop, drivability is better and smoother, which makes the racing look more realistic. The hurdles No new idea comes without some issues. One hurdle is that you lose braking capabilities. It has not been a problem here though, since good drivers know that the fastest laps are done coasting through the corners. The red controller brake lead must remain unhooked or disconnected from the circuit. Happily, there is a distinct reduction in rear end tapping sounds at the end of each straight since all the cars are now running no brakes. A second curious issue is that older diehard slot racers take a while to get used to not having the unrealistic amount of wheel spin that they were weaned on. Veteran drivers are used to gobs of wheel spinning torque as they enter a straight. The AC system is a more realistic way to run cars. The system's reduced torque is more prototypical in that you must exit a turn as fast as you can, to get the highest speed at the end of the straight. No different than real racing. Believe me, the cars can go plenty fast! New guys never notice the reduced torque until we switch back to DC. Then the cars revert to the jerky, wheel spinning, limited control that we've all gotten used to. After an hour of running, even the veterans agree that it is a great smooth way to run cars. No more flying blurs darting mindlessly around the track. It takes a new mindset to drive, but it looks smooth and realistic! For scale model routed tracks, this AC system with secondary passing lanes, provides more action with the added cars, more control, more linear feet of racing in the area allowed, at a minimum of cost. Although there are double the cars on the track, the racing is smoother than with half the cars on DC. All of the GWLTRSCIOGBs who have run the past 20 months on Northline Raceway agree that they are having more fun running with larger fields of cars running with more of the look of realistic racing. Even though lap times are slower than on DC, the cars are still lapping the track 100% faster than prototypical speeds. But, with double the racing action because 8 cars are running side by side and nose to tail with much smoother control! For answers to more questions related to the operation of Northline Raceway, see the "Model Car Racing" Magazine #14. Robert Schleicher's books on Model Car racing are also a great reference. The word on building and designing wood routed scale tracks on the internet is Luf Linkert's Oldslotracer. And, for answers to questions specific to lane changing and the AC system on Northline raceway see Jimmy's FAQ on the Professor Motor web site. I am excited to share what we've learned with others who have our passion for realistic model racing and are interested in building a routed track to take advantage of all the benefits that this system has to offer. Return to Jimmy's FAQ page |